10% back in points on custom print orders. Activate now

Free delivery on orders over $59.99

Free delivery on orders over $59.99

Need a hand? Speak to a print expert today. Find a store

10% back in points on custom print orders. Activate now

Free delivery on orders over $59.99

Free delivery on orders over $59.99

Need a hand? Speak to a print expert today. Find a store

This whisky drawer gift box is a rigid packaging solution designed for premium spirits that require both strong structural protection and refined presentation.Unlike standard lift-off lid or magnetic boxes, the drawer-style structure provides better weight support for heavy glass bottles and allows smoother repeated opening during retail display. It is widely used for aged whisky releases, limited editions, and high-end gifting projects where packaging performance matters as much as visual impact.This solution is particularly suitable for brands handling export shipping and large-scale production.

Item No :

Customized Paper BoxesOrder(MOQ) :

1000Payment :

VISA、PayPal、Apple Pay、Google Pay、AlipayColor :

CustomizedShipping Port :

sea freight, air freight, logisticsLead Time :

10-15 Days Based QuantityWhisky Drawer Gift Box Packaging

Designed to Prevent Structural Issues During Mass Production and Shipping

If you are sourcing packaging for whisky, you are not simply selecting a box.

You are responsible for what happens after approval — during bulk production, transport, warehousing, and retail handling.

Whisky bottles are heavy. Glass tolerances are unforgiving.

Minor structural miscalculations can lead to deformation, drawer misalignment, or internal movement once production scales.

This drawer-style rigid box is developed for buyers who prioritize predictable structural performance over decorative complexity.

Why Drawer-Style Boxes Are Preferred for Heavy Whisky Bottles

Many whisky brands move to drawer-style packaging after encountering issues such as:

· Outer boxes deforming under bottle weight

· Lids shifting during stacked shipping

· Internal trays loosening after transport

· Sample quality not matching bulk consistency

The sliding drawer structure separates the outer sleeve from the load-bearing inner tray, allowing weight to be distributed more evenly and reducing stress on the overall structure.

Real Usage Scenarios Buyers Consider

Before approving production, experienced procurement teams often consider:

· During sea freight, when cartons are stacked under pressure

· In distribution centers where handling is repeated

· In retail display where drawers are opened multiple times daily

· During gifting occasions where presentation reflects brand value

This packaging format is engineered with those real-world situations in mind.

Structural & Material Specifications

The whisky drawer gift box typically includes:

· High-density rigid greyboard for structural stability

· Reinforced outer sleeve for shape retention

· Custom-fitted inner tray based on bottle height and diameter

· Smooth sliding tolerance control to prevent jamming

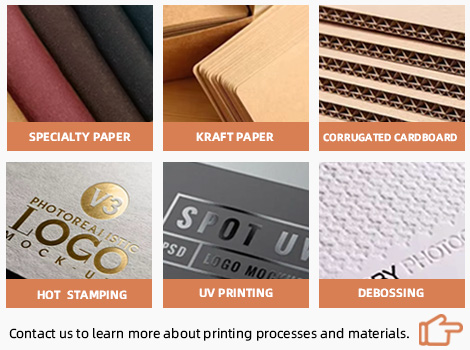

Surface finishing options include:

· Hot foil stamping (gold, silver, metallic tones)

· Embossing or debossing

· Matte or soft-touch lamination

· Specialty textured paper

All finishing applications are evaluated to ensure they do not affect drawer movement or structural integrity.

Suitable Applications

This packaging solution is suitable if:

· Your whisky bottle is heavy or thick-glass

· Export shipping stability is a priority

· Retail environments require repeated opening

· Brand positioning targets the premium segment

It may not be suitable for ultra-low-cost promotional packaging.

Why Choose Us

1.Video - shooting service for the whole production process, with 100% quality guarantee.

2.Complete set of certificates ensures excellent quality and management.

3.With over 100 employees and more than 20 years of experience, we safeguard your orders.

4.A low MOQ of 1000 pcs enables you to kick - start your customized brand packaging quickly.

5.Free design services are provided so that you don't have to worry about design issues.

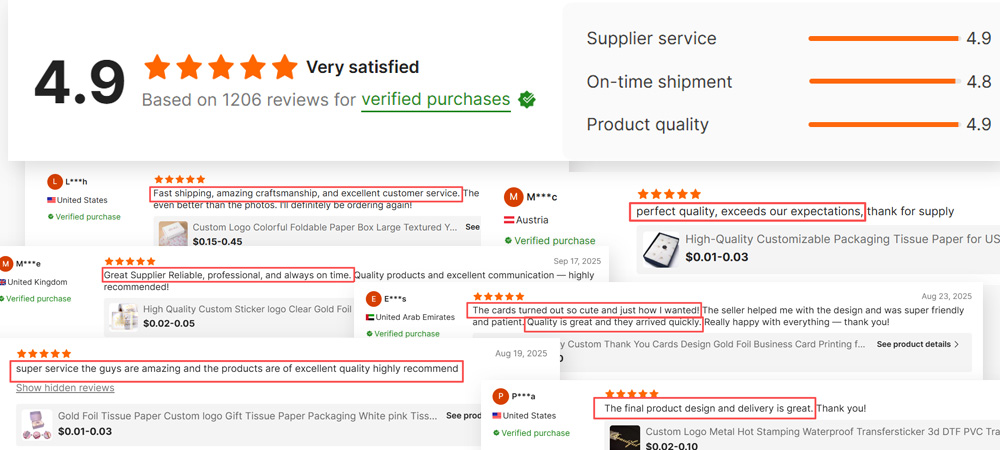

6.With over 2,000 buyers giving 5 - star reviews, we are the best supplier on www.ecoinkhub.com.

7.Integrating production and trade, we ensure high - quality products and on - time delivery.

Trusted Manufacturer, Guaranteed Quality

With a 10000㎡ factory and 20 years of production expertise, we ensure every sticker meets the highest standards. From raw materials to finished products, each label undergoes strict quality control, guaranteeing only premium quality reaches your hands.

Real Quality, Proven by Our Customers

Our Collaboration Process :

Step 1: Consult & Quote

Share your needs online, and we’ll provide a detailed quote tailored to your requirements.

Step 2: Confirm Design

Our design team offers free support to finalize your artwork and get your approval.

Step 3: Pay for Sample (Bulk orders are non-refundable)

Pay the sample fee (For orders totaling USD 1,000 or more, the sample fee will be fully credited as a discount.) and confirm the physical sample effect.

Step 4: Mass Production

Upon receipt of full payment, our factory will commence production without delay.

Step 5: Quality Check & Global Shipment

Once production is complete and quality inspection is passed, we will arrange global shipping.

FAQ (Frequently Asked Questions):

Q1: Do you offer free samples?

A1: Yes!We provide free samples—you only cover the shipping cost.

Q2: What file formats do you require?

A2: For optimal print quality, we recommend vector files (AI, PDF, CDR) or high-resolution images (300DPI or above).

Q3: How long is the production lead time?

A3: Samples take 3–5 business days. Bulk production typically requires 5–10 business days after sample confirmation.

Q4: Do you ship worldwide?

A4: Absolutely!We support global express shipping with professional logistics packaging.

Q5: Payment Methods:

A5:VISA、PayPal、Apple Pay、Google Pay、Alipay

Q6: Do you accept installment payments or partial/prepaid payments?

A6:Yes,Please contact us to discuss the best payment plan for your order.

Q7: Can I print my own logo or design?

A7: Yes, fully customizable. Just send us your logo/artwork.

Q8: What material is best for outdoor use?

A8: PVC vinylis waterproof, UV-resistant, and perfect for outdoor durability.

Q9: What shapes can I order?

A9: Any shape — we cut exactly as per your design. No background needed.

Q10: Do you offer design services?

A10: Yes, we provide free basic design/layout check and advice.

Discuss Structure Before Mass Production

Most packaging issues occur during scaling rather than sampling.

If you are evaluating drawer-style whisky packaging, you may first review bottle specifications, weight distribution, and shipping conditions before finalizing design.

You are welcome to discuss your packaging requirements to assess structural feasibility prior to mass production.

Blog Sitemap Xml Privacy Policy

Copyright © 2026 GuangZhou Guyin Packaging Co., Ltd. All Rights Reserved.  Network Supported

Network Supported

Leave A Message

Scan to WhatsApp :